Vertical bayonet vaporizers are good general use vaporizers. The flexibility that numerous materials of construction combinations can provide allows these vaporizers to be used for a wide variety of process fluids. Armstrong Chemtec is a preferred supplier for multiple licensed refinery processes and has a long history of providing these vaporizers for chlorine service. Armstrong Chemtec is a member of both the Chlorine Institute and Euro Chlor, and has participated on multiple task groups to review and revise Chlorine Institute’s Pamphlet No. 9, including the two most recent editions.

Vertical bayonet vaporizers are good general use vaporizers. The flexibility that numerous materials of construction combinations can provide allows these vaporizers to be used for a wide variety of process fluids. Armstrong Chemtec is a preferred supplier for multiple licensed refinery processes and has a long history of providing these vaporizers for chlorine service. Armstrong Chemtec is a member of both the Chlorine Institute and Euro Chlor, and has participated on multiple task groups to review and revise Chlorine Institute’s Pamphlet No. 9, including the two most recent editions.

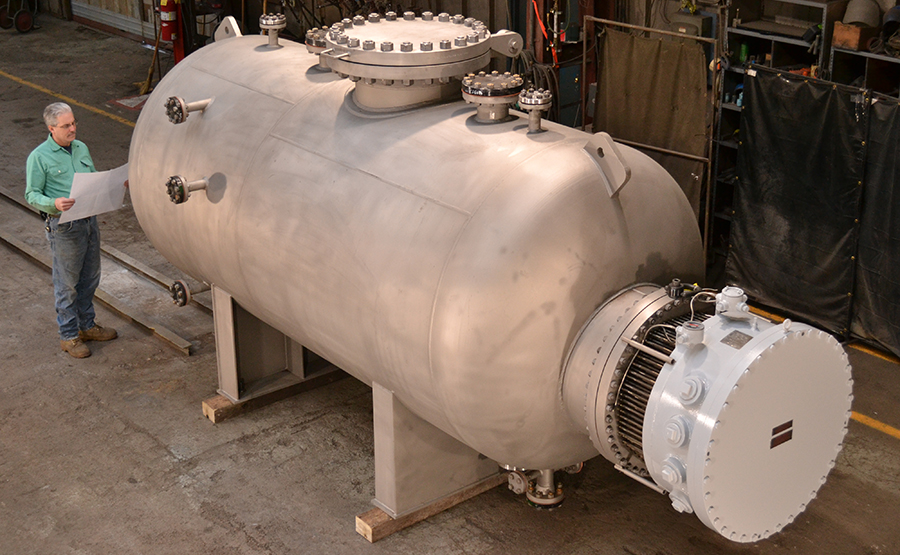

Loadout vaporizers are steam heated and well suited to handle combinations of very high pressures (design pressures up to 120 bar (g) (1,800 psi) and very low temperatures (typically around -74 °C ( -101°F) ) because they do not have tubesheets. Because these vaporizers can go from an idle state to full capacity instantaneously, they are frequently called on to replace or supplement feed to downstream processing units.

Flare superheaters can be used to heat the flare gas stream from temperatures as low as -73 °C ( -100 °F) and can accommodate low allowable pressure drops.

When a steam utility is unavailable, electric heat may be a safe sensible first choice option. Electric heaters have been used in off site tanks for bituminous products for many years. But recently, with the move to environmentally friendly processes, and zero emissions at point of use, Electric Vaporizers have been put into service for fluids such as NH3, CO2, SO2, SO3 etc. These can be supplied skidded with valves, pumps, controls and piping. These are now commonly found in power stations where NOx and SOx emission reduction systems are used. Contact us for your needs and let us help you make a proven environmentally friendly choice.

P: (1) 610-436-6080

E: sales@armstrong-chemtec.com

P: (44) 1505-502206

E: uksales@armstrong-chemtec.com

P: (65) 9325-1010

E: asiasales@armstrong-chemtec.com

P: (1) 610-436-6080

E: sales@armstrong-chemtec.com

P: (44) 1505-502206

E: uksales@armstrong-chemtec.com

P: (65) 9325-1010

E: asiasales@armstrong-chemtec.com